SPUN BOUND POLYPROPYLENE

CARTRIDGE FILTERS

COMMON FEATURES

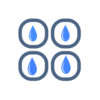

30 inch and 40 inch cartridge filters

Progressive pore depth filtration

All products are manufactured with progressive pore filtration technology. This provides a tapered pore in the filter depth of the cartridge to increase the dirt holding capacity of the filter and its service life.

Food grade materials

All of our products are made from melt blown food grade polypropylene with FDA approval

Surface finishes

A variety of surface finishes are available to suit the application. More details below

Filter ratings

Unless stated otherwise, all cartridge filters listed here are nominal rated as is standard for the industry. The ratings available are 1, 5, 10 and 20 micron.

30 inch and 40 inch cartridge filters

Surface finishes available

Deep grooved finish

The deep grooves extend the surface area of this premium filter. This model has a higher density polypropylene matrix than other models

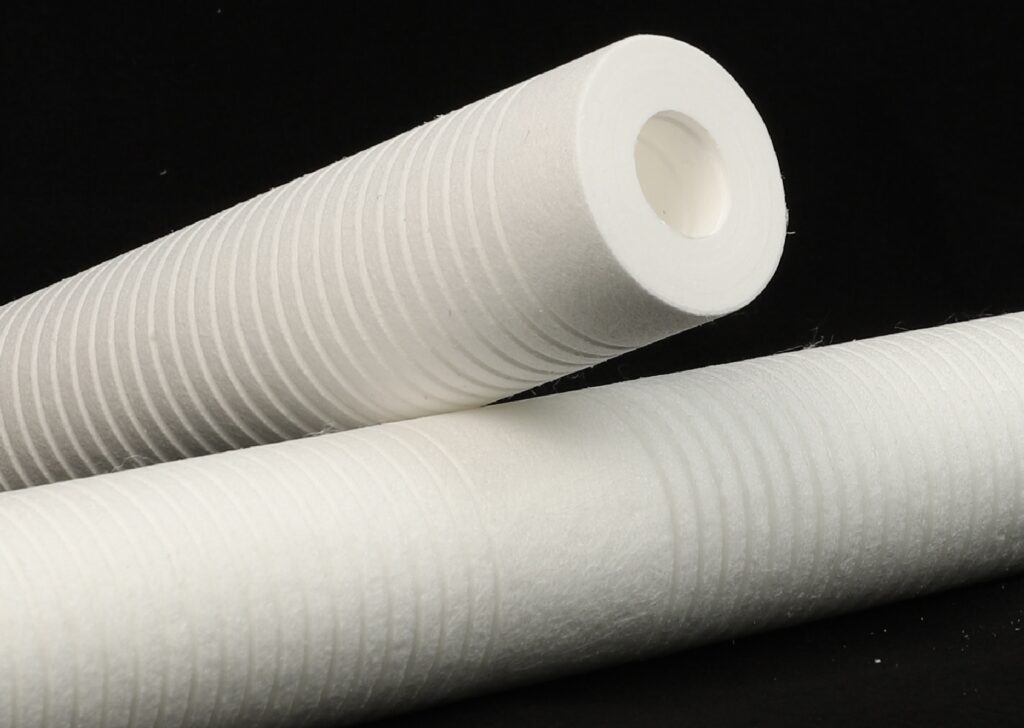

Standard finish

The surface of the filter has a a dimpled appearance and provides a high surface area. A great all round option, shown here with 224 spigot adapter and double EPDM seals

Embossed finish

The surface of the filter is embossed with concentric circles. An economical filter in all applications. Shown here with standard open ended configuration.

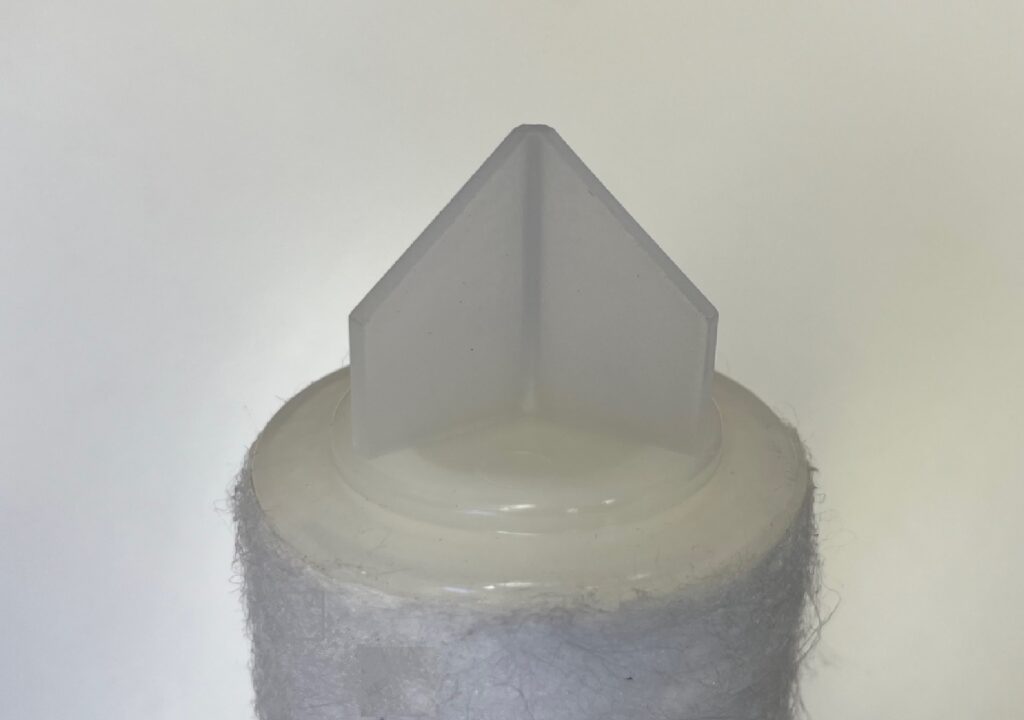

Wool finish

A highly fibrous surface texture presents a very high surface area for filtration. Shown here with 222 spigot adapter and double silicon seals

Configurations and adapters

Double open ended (DOE)

Fin

Closed end

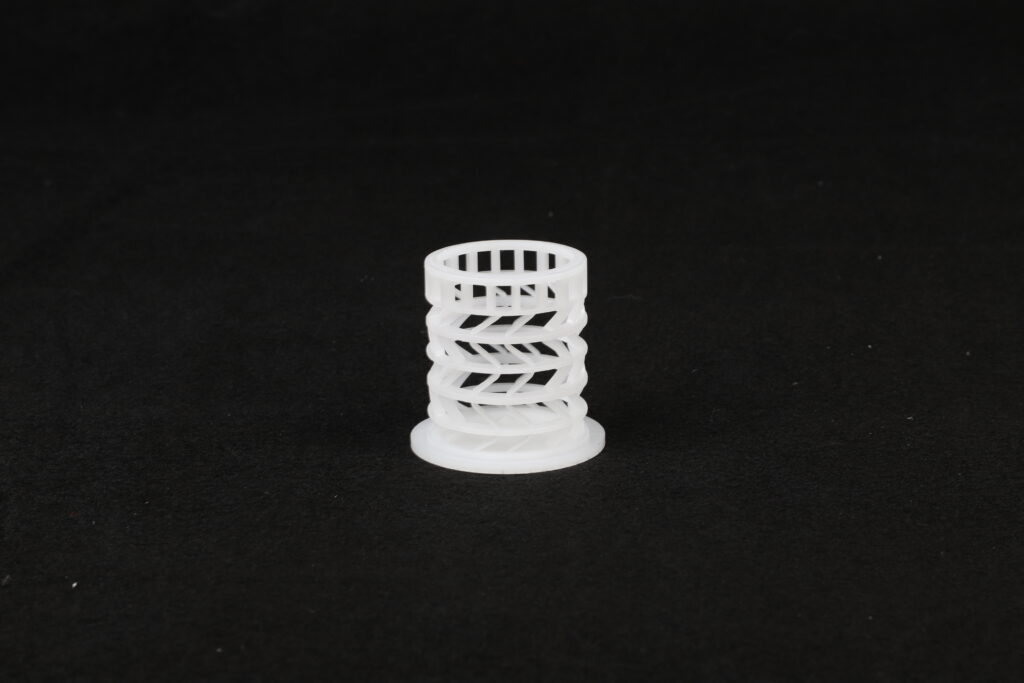

Spring

222 spigot

224 spigot

S4F configuration